News

Rozpocznijmy współpracę

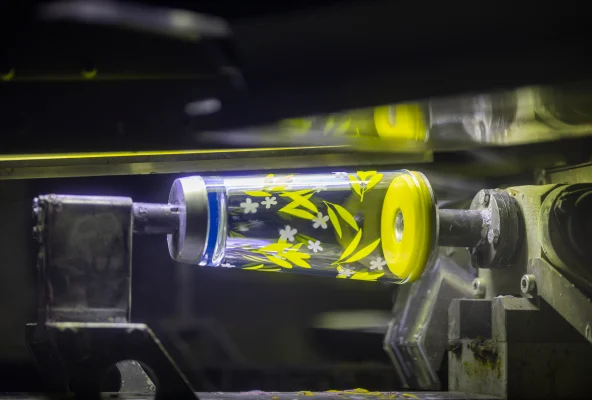

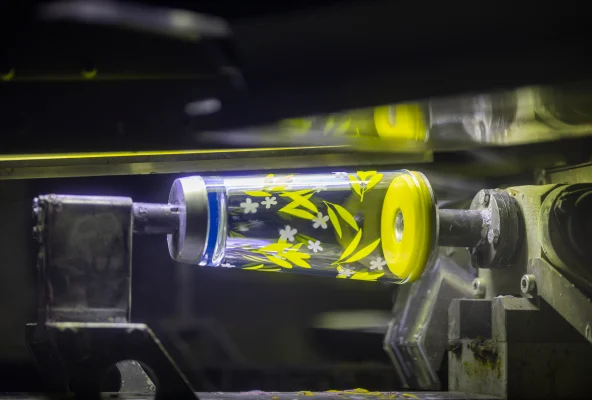

The Trend Glass plant in Radom was established in 2003 as part of expanding the production capacity of the Szydłowiec glassworks. In addition to the two smelting furnaces, Radom is home to the company’s head office, decoration facilities and the finished goods confectioning department. Due to its convenient location, the glassworks’ warehouses and logistics centre are located next to the Radom plant.

Aliquam sagittis nulla accumsan, semper est non, blandit velit. Morbi et lacus nisi. Sed congue hendrerit libero venenatis placerat.

Lorem ipsum dolor sit amet:

The Trend Group production facility in Szydłowiec has been operating continuously since 1996. The glassworks, operating under the name “Gracja” in its early years, specialised in the production of thin-walled articles manufactured using Press-Blow and Press technologies. The short distance separating the Szydłowiec plant from the Trend Glass headquarters has a positive impact on the company’s operational efficiency.

Aliquam sagittis nulla accumsan, semper est non, blandit velit. Morbi et lacus nisi. Sed congue hendrerit libero venenatis placerat.

Lorem ipsum dolor sit amet: